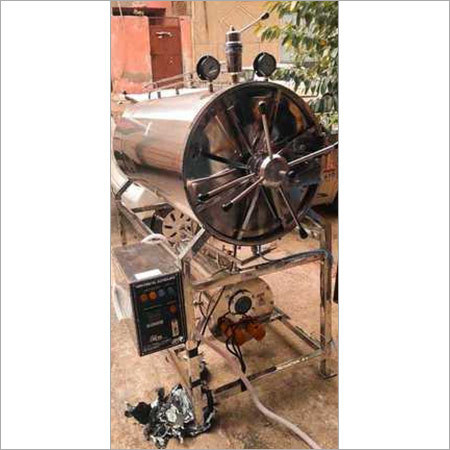

Horizontal Autoclave

Product Details:

- Usage Industrial

- Application Horizontal Autoclave

- Product Type Horizontal Autoclave

Horizontal Autoclave Product Specifications

- Industrial

- Horizontal Autoclave

- Horizontal Autoclave

Horizontal Autoclave Trade Information

- Cash on Delivery (COD) Cash in Advance (CID) Cheque

- 10 Per Week

- 10 Days

- Yes

- Free samples available with shipping and taxes paid by the buyer

- Wooden box

- Middle East Asia

- Assam South India North India East India Andhra Pradesh All India

- CE , GMP , ISO , US FDA, MSME

Product Description

Rew Horizontal Fully Automatic Autoclave

Automatic Purging for Moisture Removal

Automatic Steam Transfer

Automatic Steam Release

Soak Timer

Gasket Made of Joint less Silicon

Display Digital

Exhaust of Pressure Manual through a Exhaust Valve

Sterilizing Pressure 1.2 to 1.5 kgf. (15 to 35)PSI

Operating Pressure 15 to 35 PSI

Pressure Gouge 0-4 kgf/cm (50 Psi)

MOC Chamber 3.5mm 304 Grade

MOC Jacket 2.5mm 304 Grade

MOC Boiler 3mm 304 Grade

MOC Door Lid 12mm 304 Grade

Power Supply 440 Volts 3 Phase Supply

Features

REW Horizontal Triple Walled Autoclaves are most ideal for critical applications requiring assured and reliable total destruction of all living micro-organisms.

All ideal tool for Laboratories, hospitals, nursing home, R&D labs, etc.

The inner chamber, steam jacket, outer chamber, and boiler are made of heavy gauge stainless steel with leak-proof argon arc welding.

Lid is made of thick machined Mild Steel plate lined with stainless steel from inside

The space between the outer chamber and steam jacket is filled with glass wool to minimize thermal losses.

Hydraulically tested to withstand 2.5 times the working pressure.

Steam boiler is fitted with water level indicator, pressure gauge, low water cut-off device, and automatic pressure control device.

Fitted with safety valve as a safety device.

Drain valve is fitted at the side bottom for easy draining/cleaning.

The unit is provided with a positive self-locking safety door which cannot be opened while the chamber is under pressure and disengages automatically when the chamber is exhausted.

This affords complete safety to the working personnel.

Two separate valves are provided for evacuating steam from inner chamber and jackets as and when desired.

The chamber discharge line is fitted with a moisture trap to absorb the condensate automatically thus preventing moistening of the loaded material to be sterilized.

An automatic vacuum breaker is fitted to all REW units as a standard accessory, in order to break vacuum in case of steam condensation.

The flange immersion-type heating element made from very high-grade material provides the fast formation of pressure in the system and are protected through an electric low water level cut-off device.

All REW Sterilizers are provided with triple safety features, through a PIEZOSTAT (Automatic Pressure Control System) and a spring-loaded safety valve fitted to the boiler/steam generator. The chamber is fitted with spring-loaded safety valve and a dead weight release valve.

Highly accurate temperature indicator is fitted for monitoring temperature.

Other Products in 'Autoclaves' category

|

RENU ENGG WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese