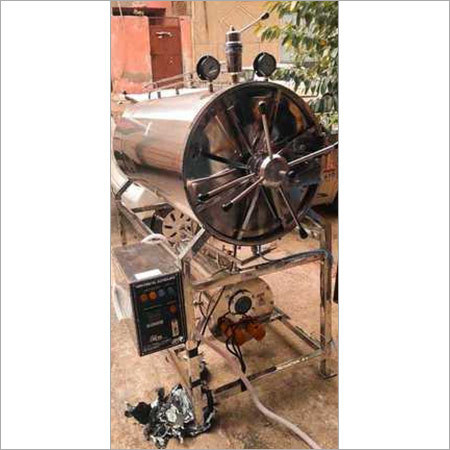

Food Sterilizer

Product Details:

- Power 18000 Watt (w)

- Dimension (L*W*H) 24*48 Inch (in)

- Material Stainless Steel

- Operate Method Fully Automatic

- Weight 350 Kilograms (kg)

- Product Type Sterilizer

- Application For Increasing Self Life

Food Sterilizer Price And Quantity

- 1 Piece

- 470000 INR/Piece

- 450000.00 - 2500000.00 INR/Piece

Food Sterilizer Product Specifications

- 350 Kilograms (kg)

- 24*48 Inch (in)

- Air Compressor

- 18000 Watt (w)

- 18 Kilowatt (kW)

- Stainless Steel

- Mist Nozzle

- Fully Automatic

- 15 PSI

- 121 Celsius (oC)

- 134 Celsius (oC)

- Hinged Type Door

- For Increasing Self Life

- Stainless Steel

- 350 Kilograms (kg)

- Sterilizer

- Glass Wool

- USB Attachment

- Stainless Steel

- 350 Liter/day

- Stainless Steel

- Stainless Steel

- 30 Minutes

- 30*56

- 24*48

- 121 Celsius (oC)

- 134 Celsius (oC)

- 440 Volt (v)

- Stainless Steel

- Pure Steam

- Sterilization

- 3: Millimeter (mm)

- 30

- Soloned Valve

- Pressure Steam Sterilization Equipments

- Glass Wool

Food Sterilizer Trade Information

- Transportation

- Cash in Advance (CID)

- 10 Piece Per Month

- 20 Days

- Yes

- Contact us for information regarding our sample policy

- Wooden Box

- Asia

- All India

- ISO CE GMP WHO US FDA

Product Description

Retort Processing Unit consisting of a horizontal retort,pump for coolant water,

The details are as follows.

1. With radial locking system.

2. Capacity: 15 kg of products packed in pouches/cans

3. The trays made of Stainless Steel perforated sheets 3 mmthick

4. Appropriate insulation with SS cladding.

5. With pressure gauge, safety valves and calibratedthermometers.

6. Provision (probes) to measure product temperature at threedifferent locations and another probe for recording retort chamber temperature.

7. With automated Fo value calculation system.

8. Fully automated Program Logic Controller (PLC), based control system.

9. Steam, air and coolant water injection lines withnozzles/sprayers, Neoprene gasket etc.

10.Retort inner chamber and outer cover made of good quality304 steel

11.Retort fully insulated as specified.

Operating Pressure and Temperature: 25 PSI max 130 Deg C max

Steam Generators: Suitable steam generation facility withimmersion heater of 9 KW cap each with control Panel to set process temp,pressure and low level cut off to protect the immersion heaters. The processwater can be replenished by the coolant high pressure pump.

Water spray System: Acirculation pump in SS with an inline steam injection system to enable theretort to work under water spray technology. Provision for automatic regulationof water level in retort.

Interconnecting Pipelines: The interconnecting lines withisolating valves located at convenient points for easy operation. The entirepipeline required during installation to fit into given space must be providedby the firm.

Supporting Structure: The supporting structure made of good quality stainless steel square orround tubes. Structure must accommodate tank to store coolant water and act asdrain tank.

Accessories and utilities:

*Suitable compressor with SS pipeline connecting the retort

*Storage tank with connecting pipeline in SS

*SS trolleys 3 ft x 2 ft with Aluminum perforated trays

*Any other accessory required for successful running of thesystem

Installation and commissioning Safety certifications to besubmitted: Above plant and utilities must be delivered, installed andcommissioned at our Centre without any extra cost.

We can provide you with the premium hot water spray retorts.The batch Hot water Spray Retort heated with water under pressure are perfectfor beverages and other food industries.

In this Hot Water Spray Retort Steam boils the water in aseparate tank and make it 121 C inside the food / bottles centre area. Since itis indirect methods of making the product sterilize. It will give good textureand taste. Boiler will remain active during making water 121 C and then productat 121 C.

Features

1.The Hot Water Spray Retorts allow for pasteurization withminimum process water, direct heating and indirect cooling. These will be notouch between cooling water and process water, successfully avoiding secondarycontamination.

2.The Hot Water Spray Retorts also boast perfect pressurecontrol. During the whole processing procedure, the pressure is constantlyadjusted to adapt to the changing pressure inside product package. They ideallykeep package deformation to a minimum, well suitable for Gas packaging and twopiece can packaging.

3.The noise of Hot Water rain retorts is extremely lowcreating a quiet and comfortable working environment.

4.The advanced and suitable DELTA PLC control system ensuresour clients are able to timely locate replacement parts of the batch retortsacross the world reducing down time.

5.The Hot Water Spray Retort / Sterilization equipment makesit convenient to configure automatic corollary equipment for unmanned foodworkshops in the future.

6.The whole sterilization process adopts PLC fully automaticlinearity control via the PLC control, the temperature difference of thermaldistribution is limited within ± 0.5C. The Hot Water Spray Retort Sterilizerallow for multi-stage heating, effectively saving energy. It also has anadditional F value recorder (optimal) capable of storing 100 scheduled process

Applications

The Hot Water Spray Retorts are well application for a widerange of thermal resistant packaging materials.

1.Plastic Container : PP Bottles, HDPE Bottles.

Other Products in 'Autoclaves' category

|

RENU ENGG WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese